SPINDLES

REPAIRS

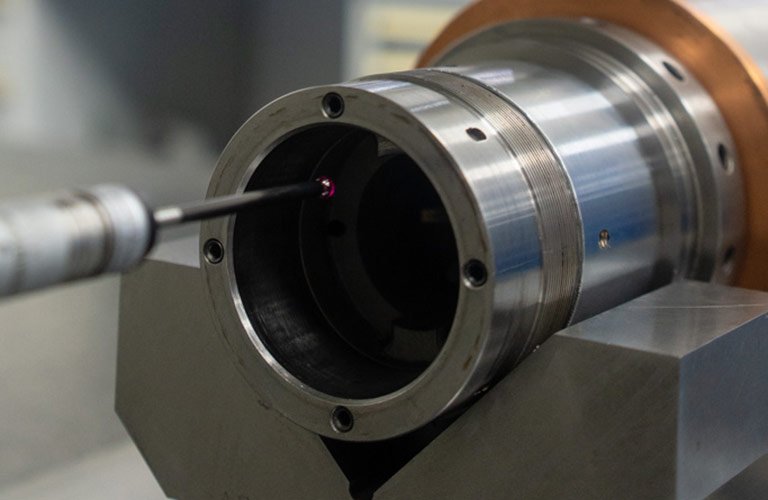

We repair spindle heads of different brands and models.

We have extensive experience in repairs of heads of different brands and models. Therefore, we can offer you a series of packs that cover the most common repairs and services.

We explain how our repair service Works below. It is a complete service with three phases: before, during and after the repair.

REPAIRS

GOALDE HIGH SPEED’S REPAIRING SERVICE PACKS

We have prepared some packs with different services of the three phases in the repair process so that you can choose the one that best suits your needs.

SERVICE

PACKS

01

PREVIOUS

SUPPORT

PACK

Choose this pack for incidents that require support before disassembling the spindle from the machine Discover the verifications included in our protocol.

Choose the diagnostic pack to identify the damage and what exactly needs to be repaired

DIAGNOSIS

Through this service:

- We identify the cause of the damage.

- We indicate precisely the elements that need to be replaced or repaired.

- We make a specific and accurate assessment of the necessary repair.

- This service is free, you just have to take care of the shipping and collecting costs.

More information about the diagnostic service.

SERVICE

PACKS

03

PACK

DIAGNOSIS

+ REPAIR

Choose this pack to know the reason for the breakdown and repair it.

DIAGNOSIS

Through this service:

- We identify the cause origin of the damage.

- We indicate precisely the elements that need to be replaced or repaired.

- We make a specific and accurate assessment of the necessary repair.

- This service is free, you just have to take care of the shipping and collecting costs.

More information about the diagnostic service.

REPAIR

Having previously made the diagnosis, we know the specific characteristics of the spindle and we can face a repair with full guarantee and according to our high quality levels.

More information about the repair service.

SERVICE

PACKS

04

PACK

DIAGNOSIS

+ REPAIR

+ SUPPORT

INSTALLATION IN MACHINE

Choose this complete pack to identify the damage, repair it and start the machine successfully.

DIAGNOSIS

Through this service:

- We identify the cause origin of the damage.

- We indicate precisely the elements that need to be replaced or repaired.

- We make a specific and accurate assessment of the necessary repair.

- This service is free, you only have to take charge of the costs of the shipping and collecting costs.

More information about the diagnostic service.

REPAIR

Having previously made the diagnosis, we know the specific characteristics of the spindle and we can face a repair with full guarantee and according to our high quality levels.

More information about the repair service.

SUPPORT FOR MACHINE INSTALATION

In some cases, it is essential to add this service to the machine’s repairing and maintenance in order to guarantee the success of the launch.

For us, the repairing process only ends with a satisfactory installation on our client’s machine.

More information at the support service for machine installation.

SERVICE

PACKS

05

PACK

HOSTEL SERVICE

We recommend this service for machines tool’ manufacturers that have several spindles of the same type. With Hostel Service we take care of storing them properly and we make sure they are in the best conditions.

Enjoy this pack for only 150 euros per year.

PUSH – EMERGENCY SERVICE

We attend immediately any problem with the spindles’ operation.

Discover our push service

Is it an emergency?

Activate the push service by pressing this button

PREVIOUS PHASE

01

PREVIOUS

SUPPORT

Sometimes, starting the diagnosis on the machine itself is crucial to find the right solution. Therefore, this service takes place before disassembling the spindle from te machine.

Our wide experience with different models of spindles and machines allows us to provide a qualified vision centered on the machine head.

VERIFICATIONS INCLUDED IN THE PREVIOUS SUPPORT

In our previous support we approach the analysis with the following verifications stipulated in our protocol:

- Control of the clamping system and clamping force.

- General checks of the lubrication system, cooling …

- Control of jumps and axial displacements.

- Control of encoder signals.

- Vibration analysis.

- General inspection of the machine.

When we receive the spindle in our facilities, we identify it, enter it into the system and assign it a project number for traceability.

PREVIOUS PHASE

03

INITIAL

INSPECTION

We thoroughly inspect the spindle to analyze the conditions we received it. This way we analyze the possible damage before disassembling it.

INITIAL INSPECTION CHECKING

Upon receiving the spindle we perform the following checks:

- Visual inspection.

- General checks of the lubrication system, cooling …

- Vibration analysis.

- Control of the clamping system (force, height of the clamp, conditios of the clamp and cone …).

- Jumps to 300 mm.

- Jump in front and cone.

- Control of axial displacement.

- Control of encoder signals.

- Verification of eventual electric short circuits

PREVIOUS PHASE

04

DISASSEMBLY

We completely disassemble the headboard: we identify and separate each one of the components without damaging them.

Next, we digitally store the data related to the condition of the pieces.

PREVIOUS PHASE

05

CLEANING

We thoroughly clean critical parts and make sure they are in the best conditions for geometric inspection.

PREVIOUS PHASE

06

GEOMETRIC

INSPECTION

- We perform a dimensional and geometric inspection of the critical components, paying special attention to coaxiality.

- We guarantee the accuracy of the measurements since the temperature of our facilities is under control and in constant conditions.

PREVIOUS PHASE

07

REPORT

AND BUDGET

All the departments together analyze the data and prepare a report with a personalized budget.

REPAIR PHASE

01

PLANNING

Once the budget is accepted, we plan the repairing in the most efficient way to respond within the deadline and the particular needs of each client.

REPAIR PHASE

02

PROVISIONING

DESIGN AND MANUFACTURING.

Depending on the type of repairing, we take care of getting the components that have to be replaced or we design and manufacture them in our facilities.

REPAIRING PHASE

03

ASSEMBLY

Once we complete and finish the cleaning of the parts, we proceed to the assembly of the spindle. During the assembly process we are very meticulous in all areas: mechanical, electrical and electronic.

REPAIR PHASE

04

ELIMINATION

AXIS JUMP

/ BALANCING.

We balance the spindle to the highest level defined in ISO-10816.

REPAIRING PHASE

05

VALIDATION AND OPERATION TEST

The person responsible for this analysis is the technician who carried out the initial inspection and disassembly of the spindle. In this way, the same professional is responsible for the entire repairing process:

- We validate the electrospindfles mechanically, electrically and electronically according to the proper control parameters.

- During the process we check the vibration levels and the temperature of the bearing and the motor.

- We carry out an exhaustive analysis of all the values that lead to the correct operation of the spindle.

Once this stage is finished, the spindle is ready to be installed in the machine with a good operation guarantee.

Checkings in the operation test

- Vibration analysis.

- Lubrication system checking

- Checking the cooling system

- Control of the clamping system

- Clamping force.

- Jumps to 300 mm

- Jump in frontal side and cone.

- Control of axial displacement.

- Control of encoder signals.

REPAIRING PHASE

06

DISPACH

We guarantee the best transport of the machine head because we use both a packaging adapted to each spindle and anti-shock systems.

FINAL PHASE

01

POSTERIOR SUPPORT:

INSTALLATION SUPPORT IN MACHINE.

To achieve this start-up with guarantees of success, in certain cases this support is an essential complement to the rest of maintenance tasks of machine repair.

With this service we make sure that once the spindle is installed in the machine, the values and parameters validated in our test benches are maintained. These values and parameters determine the correct operation of the spindle in the machine.

Our wide experience with different models of electric spindles and machines allows us to provide a qualified vision focused in the machine head

FINAL PHASE

02

HOSTEL SERVICE

We recommend this service for manufacturers of machines that have several spindles of the same type.

Machine head storage service:

- We keep the spindle in Goialde and at least once a year we review it with a process similar to that for repair validation and good performance test. This way we make sure that it is in the best conditions.

- With a simple telephone call, you will have your electric spindle in a few hours in perfect conditions to replace the one that is broken or is in the machine’s maintenance process.

Enjoy this service for an additional cost of only 150 euros per year.

HOW TO STORE CORRECTLY AN SPINDLE

If you do not considerer this service necessary, please follow these tips to store an electric spindle properly:

- Keep the shaft inside your package.

- Store the spindle in a dry, clean and dust-free place.

- The temperature of the place must oscillate between 10ºC and 35ºC. No sudden changes.

- Please place the head on an antivibration surface.

- At the storage location the vibration level must never exceed 0.1 mm. / sec

- If it is permanent grease bearings: please every two months turn the main shaft 180º, thus ensuring that the grease spreads uniformly and does not remain accumulated on one side of the bearing.

MULTIBRAND REPAIRINGS

SPINDLES

Franz Kessler

Weiss

Siemens

Fischer

Gamfior

Ibag

PeronSpeed

DMG

Mori Seiki

Faemat

GMN

TDM

Hsd

Omlat

MYL

Mikron

Step Tec

Cytec

Jobs

MULTIBRAND REPAIRINGS